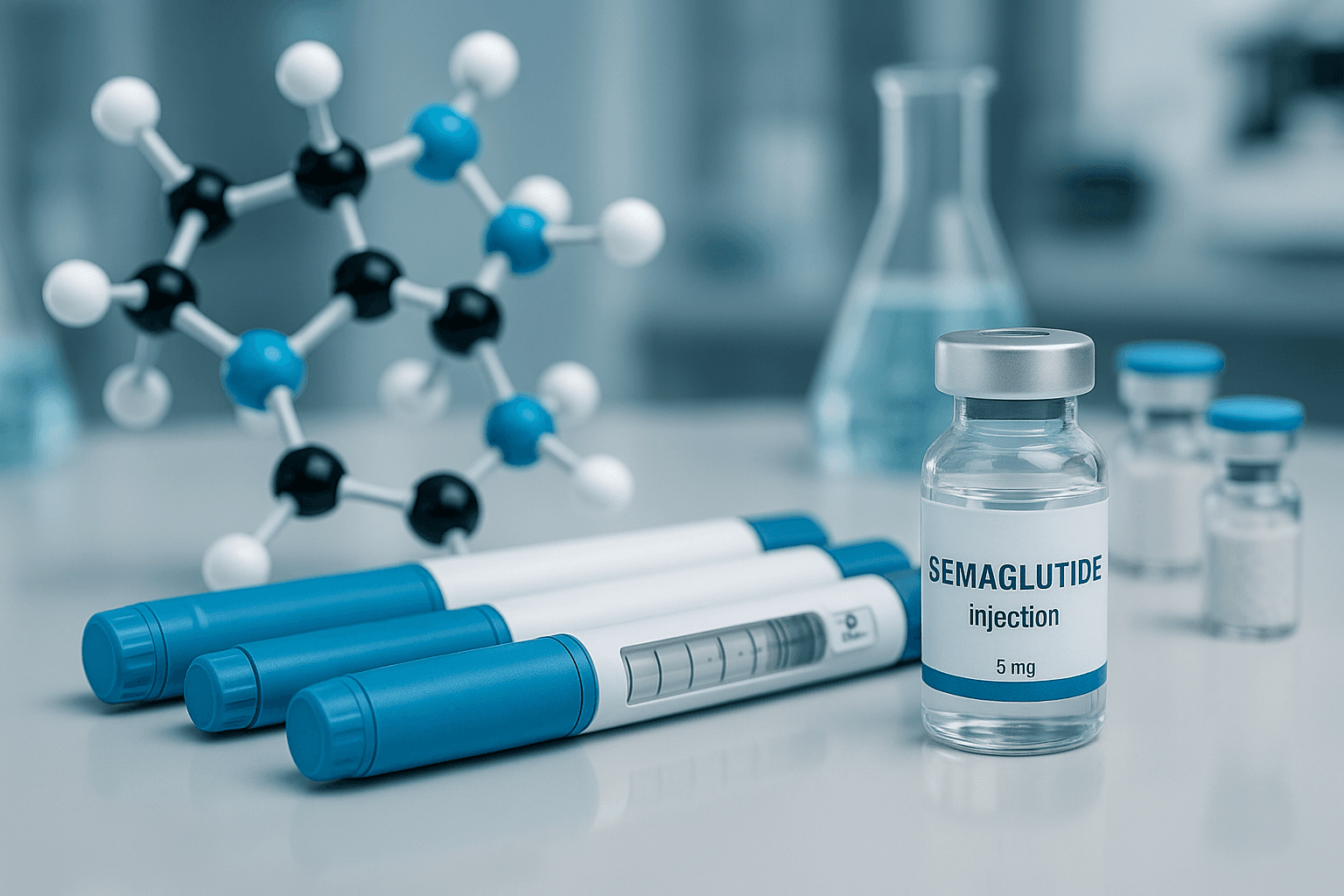

Step 2: Choose a CDCA Source.

CDCA is manufactured by pharmaceutical and chemical companies, typically in facilities that adhere to Good Manufacturing Practices (GMP).

Manufacturers of CDCA are often located in regions with a strong pharmaceutical and biotechnology industry. These facilities are equipped with the necessary infrastructure, technology, and expertise to ensure the production of high-quality CDCA that meets regulatory standards.

Some countries that produce CDCA include:

China

China is a major hub for contract manufacturing organizations that produce active pharmaceutical ingredients (APIs) and other products for the medical industry. While this may offer economic advantages, purchasing pharmaceuticals from China poses inherent risks related to product quality, safety, and regulatory compliance. Concerns about the reliability of quality control standards among different manufacturers have been raised, leading to instances of substandard ingredients, contamination, and inconsistent manufacturing practices. This variability in product quality could endanger the health of consumers, particularly when it involves medications with stringent formulation requirements.

Additionally, there are concerns about regulatory oversight due to the differences between manufacturers and their adherence to international standards. Mitigating these risks through strong due diligence, supplier vetting, and a commitment to transparent and compliant manufacturing practices is essential when sourcing pharmaceuticals from China.

India

India is another significant player in the global pharmaceutical industry, with many facilities engaged in API production. While India-sourced pharmaceuticals may have cost benefits, obtaining products may come with risks related to product quality, regulatory compliance, and supply chain integrity. Further, variations in manufacturing standards and regulatory enforcement across different facilities may exist. Instances of non-compliance with GMP, inadequate temperature and quality control requirements, or fraudulent practices have been reported in some cases. These issues raise concerns about the consistency and reliability of pharmaceutical products.

It is crucial for buyers to carefully assess the reputation and certifications of pharmaceutical manufacturers in India. Further, it is imperative that they are compliant with international regulatory standards, and it is essential to establish clear communication channels to address any quality or safety issues. Thorough due diligence and collaboration with reputable suppliers can help mitigate these risks and ensure the procurement of safe and effective pharmaceuticals from India.

Europe

Several countries in the European Union have pharmaceutical manufacturing capabilities, offering numerous benefits to many customers who buy GMP-grade APIs such as CDCA.

European suppliers typically adhere to stringent regulatory standards, ensuring the safe production and distribution of high-quality pharmaceutical products. The European Union follows GMP regulations, which set rigorous pharmaceutical manufacturing, testing, and quality control standards, ensuring a high level of assurance regarding product quality and regulatory compliance.

Moreover, European suppliers may offer transparency in their supply chain processes, allowing buyers to trace the origin and manufacturing practices of the pharmaceutical products. This transparency can enhance trust and confidence in the procurement process. Additionally, Europe has a well-established reputation for research and development in the pharmaceutical industry, and suppliers may provide innovative solutions and a diverse range of pharmaceutical products.

When considering CDCA suppliers in Europe, verifying their certifications, compliance with relevant regulations, and reputation within the industry is essential. Engaging with reputable European suppliers can contribute to a reliable and transparent global supply chain, ensuring the procurement of high-quality CDCA for various applications.